Kyzyl-Kiya, Kyrgyzstan — It may look like an ordinary building site but Akmatbek Uraimov’s new house in Kyrgyzstan is being built with blocks of rice.

The eco-friendly alternative to conventional construction materials is booming in the Central Asian country, which is vulnerable to global warming and grapples with water shortages.

Before selecting the unorthodox material, Uraimov had researched other options, but concluded that the relatively cheap blocks made from rice husks were his best option.

“In terms of insulation, cost, as well as for builders, it turned out to be convenient,” said Uraimov, who lives in the village of Kyzyl-Kiya in southern Kyrgyzstan.

“People didn’t know about it. Now they see it, they are interested, they call,” he told AFP.

Nursultan Taabaldyev is one of the pioneers of the technology in Central Asia hailed as an environmentally friendly alternative to water-intensive concrete.

In a workshop in his home region of Batken, rice dust was billowing into the air from the husks, the rough outer shell of rice which is normally thrown away or burned.

Workers with protective masks over their faces were compressing the bricks before rushing to dry them, and helping clients load the finished blocks onto trucks.

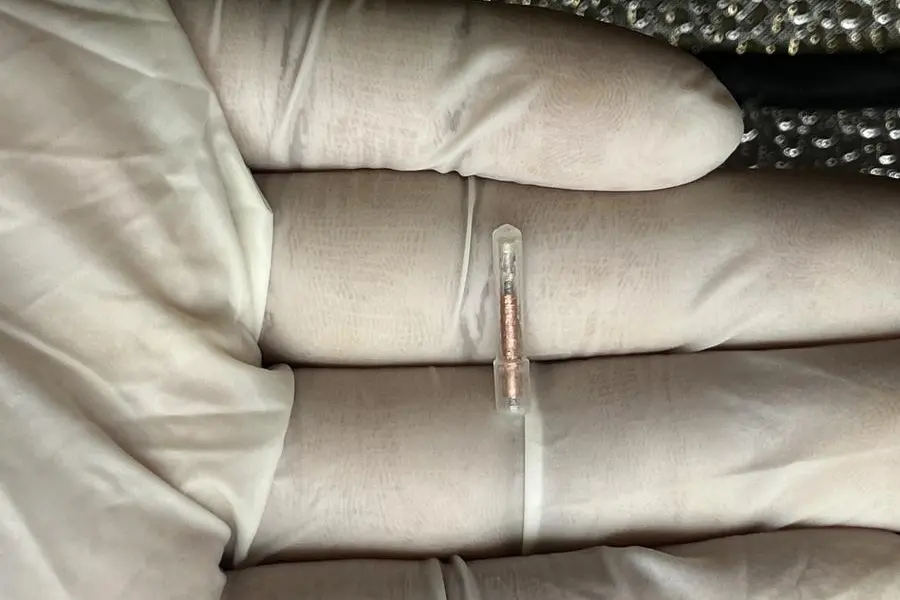

They are “made of 60 percent rice husks. The rest is clay, cement and a chemical-free glue,” Taabaldyev told AFP.

When dry, they are as strong as cement thanks to silica naturally present inside the husks.

“This idea came to me as a child, while doing carpentry with my father,” said Taabaldyev.

The 27-year-old has already built “300 houses” in five years — first with sawdust, then with rice.

‘No particular danger’

When he started, there was little robust research into the technology.

That is starting to change.

Several initial studies from various countries have highlighted the potential economic and environmental benefits of using rice blocks in construction.

Crucially, they require less cement, which is responsible for approximately eight percent of global carbon dioxide emissions, according to 2023 figures from the World Economic Forum.

In her village in a mountainous and arid region, Ykhval Boriyeva has also opted for rice blocks, praising their insulating qualities.

Her house remains “warm in winter and cool in spring” thanks to its low thermal conductivity.

“We save on coal. The walls retain heat and coolness well,” she said.

The material is also well within reach, with the Batken region producing a third of Kyrgyzstan’s rice crop.

“Rice waste is thrown into the fields, slowly burns, harms the environment, and is not used as fertiliser. So we decided to recycle it,” Taabaldyev said.

The problem of dealing with rice waste is even more acute in large rice producers like India.

There “31.4 million tons of rice husks fill landfills and cause environmental problems,” according to a study late last year published by Springer Nature.

“Farmers are happy for us to remove rice waste because its accumulation creates a fire risk” in barns if ventilation is poor, said Taabaldyev.

But as for the fire hazard to buildings made of rice, a regional official from Kyrgyzstan’s emergency situations ministry said there was “no particular danger”.

Next up ‘crushed reed’ –

Farmer Abdimamat Saparov is another who has welcomed Taabaldyev’s innovative approach, pointing at the mounds of rice waste.

“After harvesting and drying the rice, about 40 percent of waste remains, which we have no way of processing,” said Saparov.

Such abundance makes the blocks cheaper than ordinary building bricks — another crucial factor in southern Kyrgyzstan, where the average monthly salary is around $230.

Cement is more expensive in Kyrgyzstan than anywhere else in Central Asia and the government is mulling adding it to a list of socially sensitive products, alongside bread and oil, that would allow it to dampen surging prices.

Having proved the concept in the mountainous region, Taabaldyev dreams of industrialising production, expanding internationally and eyeing up even more potential materials.

“I want to go to (neighboring) Kazakhstan to make bricks from crushed reed and straw,” he said.