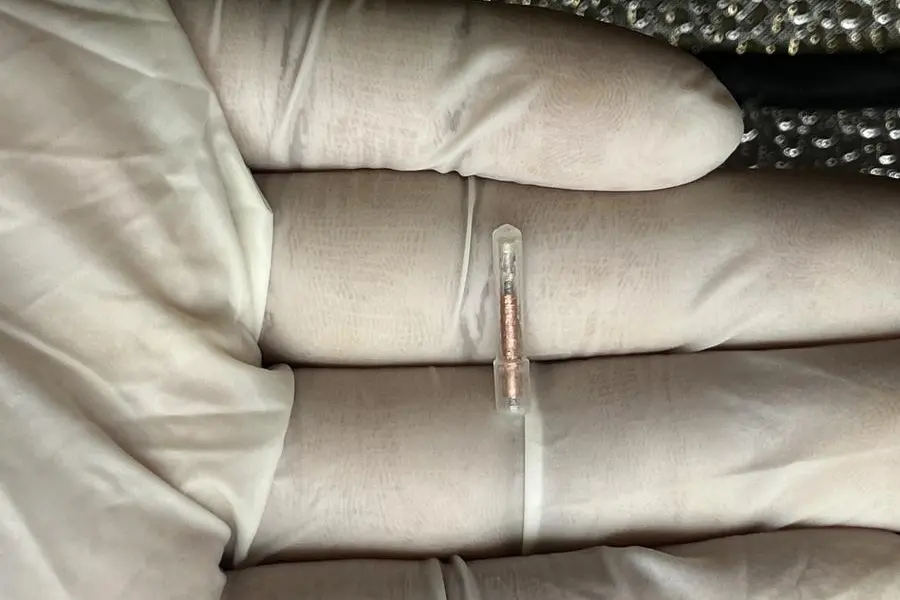

DUBAI: Saudi Aramco has opened the kingdom’s first glass fiber-reinforced polymer (GFRP) rebar facility called IKK Mateenbar, which will manufacture and supply corrosion-free fiberglass rebar for infrastructure projects in the MENA region.

The facility was established under a memorandum of understanding signed in 2019 by New Zealand’s Pultron Composites, and its partner, Isam Khairy Kabbani Group (IKK), with Saudi Aramco.

Saudi Aramco recently mandated the use of GFRP rebar in its engineering standards for reinforced concrete structures in highly corrosive environments, enabling designers to replace steel rebar in these high-risk areas.

Extreme temperatures and high levels of salinity make the kingdom one of the most corrosive environments for steel rebar, causing early structural damage, resulting in the nation’s economy incurring high costs to replace and maintain unstable concrete infrastructure.

The launch of this facility comes as part of the Kingdom’s efforts to attract and localize the rebar industry, IKK said in a statement.

GFRP rebar is the latest technology for manufacturing fiberglass rebar in New Zealand and the United States of America. It is now manufactured locally in Saudi Arabia to build better and more durable infrastructure that supports the growth of the Kingdom’s economy and enriches the quality of its environment and society alike.

Saudi Aramco was the first to deploy the innovative technology of IKK Mateenbar in the construction of its 23-kilometer-long and 80-meter-wide Jizan Flood Mitigation Channel, which is the largest GFRP rebar project in the world.

It also used fiberglass rebar to construct a bridge at King Salman Energy Park (SPARK). This is the first bridge in the country and the only one of its kind in the MENA region to use the GFRP rebar.