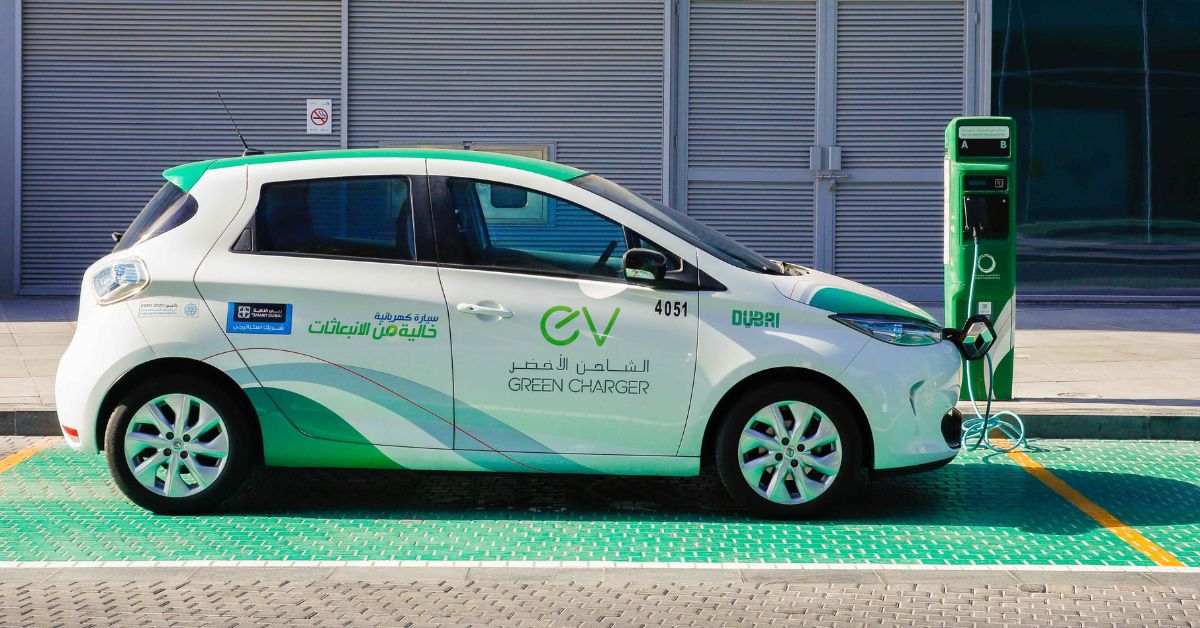

DUBAI, UAE — With the burgeoning electric vehicle industry and the shift towards clean energy, the world is predicted to face a significant shortage of precious metals like cobalt and lithium, essential for battery production, by 2030. The global count of electric vehicles is projected to surpass 115 million by 2030, a substantial increase from the 8.5 million in recent years.

Given this scenario, the Arab Gulf countries could emerge as global hubs for recycling precious metals and batteries. Their vast material resources set them apart from other nations grappling with significant crises. Moreover, these oil-rich Gulf nations have strategies in place for economic diversification.

Where does the opportunity lie?

Arshad Mansour, CEO of the Electric Energy Research Institute in Washington, in an interview with Saudi’s “Al-Arabiya” channel, highlighted that the challenge of sustaining renewable energy is not just a future concern but a present reality. This challenge will only intensify with the escalating production of renewable energies. Mansour suggests that Gulf countries, despite potentially lacking the minerals essential for the renewable energy sector, should consider establishing recycling facilities for metals, batteries, and their components. This could transform them into major global recycling hubs.

“I envision the Gulf countries evolving into recycling centers for lithium, cobalt, and rare earth elements,” Mansour remarked. “This presents a unique opportunity in the new energy paradigm, a stark contrast to the fuel-dependent system where fuel, once burned, is irretrievable.”

He further added that up to 90 percent of the lithium used in expired batteries could be reclaimed. Beyond supplying recycled metals, components, and batteries to the global market, the Gulf countries stand to save significantly by harnessing clean electricity from these batteries.

Comparing current electricity prices in the Gulf to potential future prices post the energy transition, Mansour explained, “Our analysis suggests that electricity costs could surge by 20 to 30 percent, depending on the transition’s trajectory.” He continued, “However, with a strategic shift towards clean energy, the average energy bill for a Gulf consumer, encompassing gasoline, electricity, and gas, could be lower in 2050 than it is today.”

Is this significant?

The increasing global demand for batteries and the precious metals integral to their production underscores the importance of the Gulf countries’ potential recycling approach. The value of components like lithium carbonate, natural graphite, and cobalt has already doubled, and they are anticipated to be among the priciest materials globally by 2030.

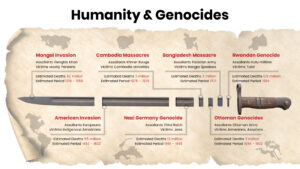

Most electric vehicles are powered by lithium batteries, which utilize a nickel-manganese-cobalt cathode and a graphite anode. Cobalt extraction is particularly concerning since a significant portion of its global supply originates from the Democratic Republic of the Congo, a region riddled with conflicts.

By 2022, cobalt prices are expected to have surged by over 100 percent, and lithium prices to have climbed by more than 30 percent, reaching a record high of $12,000 per ton by the year’s end. Electric vehicle sales are projected to rise to 14 million annually by 2025, up from less than a million currently, further driving the demand for battery materials.

Global concerns

A Reuters report from last April highlighted that the security of essential mineral supplies, especially those vital for battery production, is a growing concern for major nations, including the U.S. The International Energy Agency predicts that the demand in the sector for copper and rare earth metals will increase by over 40 percent in the next two decades. For nickel and cobalt, it’s over 60 percent, and for lithium, it’s nearly 90 percent. This could potentially hinder the pace of the energy transition.

Fatih Birol, the Executive Director of the International Energy Agency, emphasized the widening gap between the world’s heightened climate goals and the availability of critical minerals to realize those ambitions. He stressed that the journey towards a clean energy future is becoming increasingly sluggish and expensive.

The current surge in oil prices suggests that recycling batteries, their components, and precious metals could alleviate some of the global pressure on essential mineral supplies. This is especially true for Gulf countries with abundant material resources.

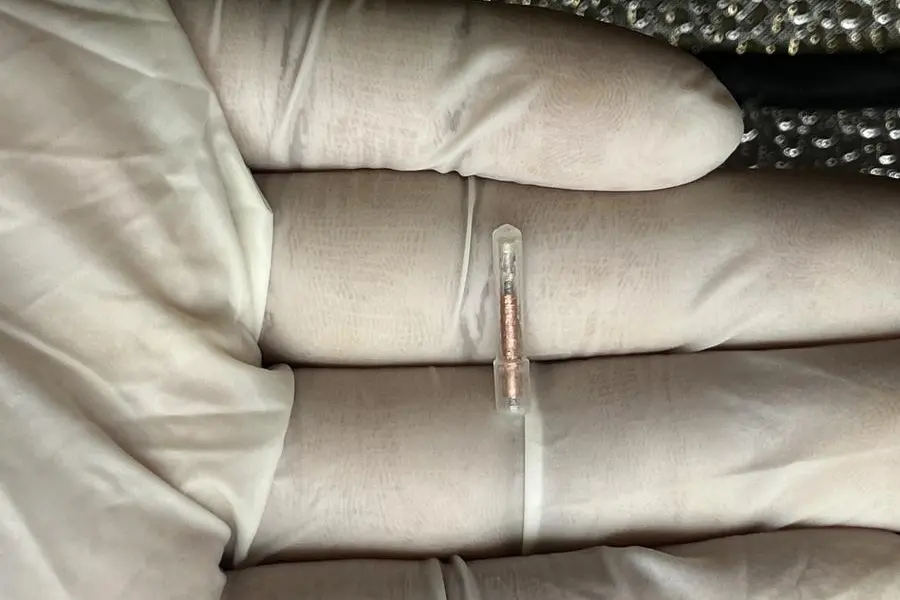

Kunal Valver, Chief Strategy Officer at Li-Cycle, a Canadian lithium-ion battery recycling firm, stated that recycling scrap from battery production is a pivotal aspect of the lithium-ion battery recycling industry. He elaborated, “As electric vehicle production scales up to meet demand, a significant portion of batteries can be recycled from the scrap generated during their manufacture.” Valver emphasized that recycling offers a more cost-effective and efficient method to obtain precious metal components, positioning it to capitalize on anticipated shortages of materials like cobalt and lithium.

However, a primary challenge currently hindering the rapid advancement of recycling processes is the scarcity of spent batteries available for recycling. This makes it challenging for the technology to be cost-effective. But industry pioneers are optimistic that as supply increases, so will profits. This constraint is due to the average battery lifespan of electric vehicles being up to ten years. However, this is expected to change by 2030 with the predicted boom in electric vehicle sales.

The sheer volume of electric vehicles sold in 2019 could result in a disposal of 500,000 tons of batteries by the time they reach their lifespan’s end, likely around 2029. A report by the U.S.-based global market research firm, Allied Market Research, estimated the global electric vehicle battery recycling market’s value at approximately $139 million in 2017. This figure is projected to soar to over $2.27 billion by 2025.