DUBAI — The growing demand for clean energy and electric vehicles signals a looming global shortage of precious metals, including lithium and cobalt, essential for battery production.

By 2030, the world’s electric car population is projected to surge from today’s 8.5 million to over 115 million. This boom is expected to strain the availability of battery metals, potentially doubling their prices and elevating them to some of the most valuable materials globally.

This scenario positions the Arab Gulf countries as potential international hubs for recycling precious metals and batteries. Their substantial financial resources, compared to other nations grappling with significant crises, coupled with their economic diversification strategies, give them a unique advantage in this emerging industry.

Where does the opportunity lie?

Arshad Mansour, CEO of the Electric Power Research Institute in Washington, highlighted the storage challenges of renewable energy in press statements last August. He noted that these challenges are already present but will intensify with increased renewable energy production.

At A Glance Global Metal Shortage Expected: Increasing demand for clean energy and electric vehicles predicts a shortage in crucial metals like lithium and cobalt by 2030. Electric Car Population Surge: Over 115 million electric cars anticipated globally by 2030, potentially doubling battery metal prices. Gulf's Recycling Opportunity: Gulf countries poised to become major recycling hubs for precious metals and batteries. Cost Benefits of Clean Energy: Transition to clean electricity may lead to long-term cost savings in the Gulf. Cobalt and Lithium Prices Soar: Significant price increases in cobalt and lithium due to supply concerns. Electric Vehicle Sales Boom: Sales expected to reach 14 million annually by 2025, increasing demand for battery materials. Global Energy Transition at Risk: Rising demand for critical minerals could slow down the clean energy transition. Recycling as a Solution: Emphasis on recycling batteries and metals to alleviate global mineral supply pressure. Challenge in Battery Recycling: The need for a sufficient supply of spent batteries to make recycling operations viable. Anticipated Growth in Battery Waste: Rise in electric vehicle sales to result in significant battery waste by 2029. Growth of Battery Recycling Market: The market is expected to reach over $2.27 billion by 2025.

Mansour suggested that the Gulf countries, despite potentially lacking the minerals for renewable energy production, could establish facilities to recycle metals, batteries, and their components, thus becoming major global recycling centers.

“I can see the Gulf countries becoming a recycling center for lithium, cobalt, and rare earth elements,” Mansour remarked. “This presents a unique opportunity offered by the new energy system, which is absent in the fuel-based system since fuel cannot be reclaimed once burned.”

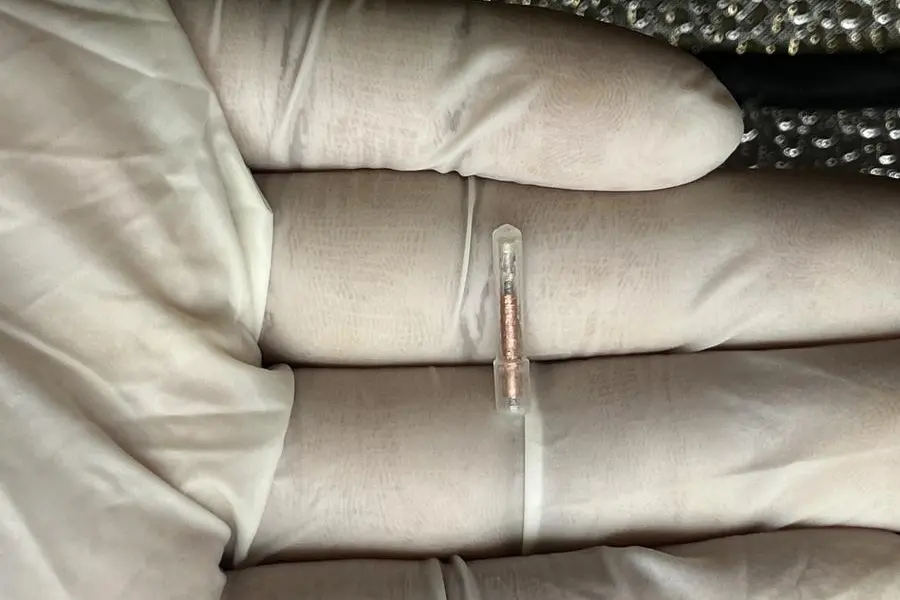

He noted that up to 90 percent of lithium in end-of-life batteries could be recovered.

I can see the Gulf countries becoming a recycling center for lithium, cobalt, and rare earth elements.

Arshad Mansour, CEO, Electric Power Research Institute

Beyond the benefits of supplying recycled metals, battery components, and complete batteries to the global market, transitioning to clean electricity through these batteries could result in significant long-term cost savings for the Gulf countries.

“If you compare today’s electricity prices in the Gulf with those anticipated post-energy transition, what differences can we expect?” Mansour inquired. “Our analysis suggests it depends on the transition’s nature, but a 20 to 30 percent increase in electricity costs is likely.”

He further elaborated, “If we manage the shift to clean energy correctly, the average Gulf consumer’s total energy bill—encompassing gasoline, electricity, and gas—will be less expensive in 2050 compared to the combined costs today.”

But why is this significant?

The Gulf countries’ move towards recycling batteries and the precious metals used in their production is crucial because components like lithium carbonate, natural graphite, and cobalt are predicted to become the world’s most expensive materials before 2030. Most electric vehicles rely on lithium batteries, which include a nickel, manganese, cobalt cathode, and a graphite anode.

There’s a growing disparity between the world’s escalating climate ambitions and the availability of critical minerals needed to achieve these goals.

Fatih Birol, Executive Director, International Energy Agency

A particular concern is cobalt extraction, as the majority of the global supply originates from the Democratic Republic of the Congo, an area prone to conflicts. By 2022, cobalt prices had more than doubled, and lithium prices surged by over 30 percent to a record $12,000 per ton by year-end.

Additionally, electric vehicle sales are projected to hit 14 million annually by 2025, up from less than 1 million. This surge will drive further increases in battery material consumption.

The global concern persists. A Reuters report from last April highlighted that key mineral supplies, especially those used in battery production, have become a significant concern for major countries, including the United States. The International Energy Agency forecasts that sector demand for copper and rare earth metals will rise by over 40 percent in the next two decades, with increases of more than 60 percent for nickel and cobalt, and nearly 90 percent for lithium. This growing demand poses a risk of slowing down the energy transition.

As electric vehicle production ramps up to meet demand, a significant amount of manufacturing scrap can be recycled.

Conal Valver, Chief Strategy Officer, Li-Cycle

Fatih Birol, Executive Director of the International Energy Agency, highlighted a crucial issue in statements last year. He noted a growing disparity between the world’s escalating climate ambitions and the availability of critical minerals needed to achieve these goals. He emphasized that the global journey towards a clean energy future is becoming increasingly slow and costly.

In light of the current surge in oil prices, recycling batteries, their components, and precious metals—especially in financially robust Gulf countries—could alleviate some of the global pressure on essential mineral supplies.

According to Reuters, Conal Valver, Chief Strategy Officer at Li-Cycle, a Canadian lithium-ion battery recycling company, emphasized the importance of recycling scrap generated during battery production within the lithium-ion battery recycling industry.

“As electric vehicle production ramps up to meet demand, a significant amount of manufacturing scrap can be recycled,” he said. “All the valuable materials found in scrap and end-of-life batteries can be repurposed for new electric vehicle batteries.”

Valver pointed out that recycling offers these precious metal components at a lower cost and more efficiently, positioning the industry to capitalize on the anticipated shortages of materials like cobalt and lithium.

However, one challenge currently impedes the rapid expansion of recycling operations. The primary hurdle for recyclers is the need for a sufficient supply of spent batteries to make their technology cost-effective. Yet, those who have already ventured into this industry remain confident that both supply and profits will eventually increase.

This challenge is partly due to the average lifespan of an electric vehicle battery, which is about ten years. This scenario is expected to change starting in 2030, coinciding with the anticipated spike in electric vehicle sales. The electric vehicles sold in 2019 alone are projected to yield 500,000 tons of battery waste at the end of their life cycle by 2029.

According to a report by Allied Market Research, published at the end of 2021, the global electric vehicle battery recycling market, valued at approximately $139 million in 2017, is forecasted to escalate to over $2.27 billion by 2025.